Custom Pouches

Stickers & Labels

Custom Boxes

Custom Cards

Cannabis Packaging

Stationery Series

Didn't find the right type?

Online Contact!

0086:18926054779

By Type

By Material

By Use

By Feature

Search

Cart

- Summary

- Orders

- My samples

- Discount

- Artworks

- Favorites

- Payment

- After-sales

- Notifications

- Setting

- Log out

Design & Guides

2025/08/17

How to Make Custom Mylar Bags — Step-by-Step Guide for Businesses

Tag:

#How to make mylar bag

#custom Mylar bags

#flexible packaging supplier

#Mylar packaging guide

Share:

From the aroma of freshly roasted coffee to the crisp snap of a well-sealed snack pouch, packaging does more than protect a product — it shapes how customers experience your brand. Mylar bags, with their superior barrier protection and sleek finish, have found their way into industries as varied as food, coffee, snacks, pharmaceuticals, and cosmetics.

For businesses, going custom is about more than just looking different. It's about putting your brand into customers’ hands, standing out on crowded shelves, safeguarding authenticity, and meeting industry regulations with confidence.

In this guide, we'll take you from the spark of an idea to the finished Mylar bag — showing you each step of the production journey so you can make smart, informed decisions for your business.

Define Your Packaging Requirements

Before starting the custom Mylar bag production process, it's essential to clearly define your packaging goals.Your intended use will influence material choice, bag style, surface finishs, special process, printing method and compliance requirements.

Find out which bag type is right for your product:

| Bag Type | Application | Structural Features |

| Stand Up Pouches / Stand Up Pouches with Zipper | Suitable for various products including snacks, coffee, tea, pet food; can stand upright for better display and storage | Bottom gusset design allows the pouch to stand upright; optional zipper for resealability; made from laminated materials for durability |

| 3 Side Seal Pouches | Common for single-use or smaller quantity products like food, powder, snacks, and pharmaceuticals | Sealed on three sides with one open end for filling; available in various materials; provides good barrier properties |

| Quad Seal Bags | Often used for coffee, pet food, and other heavier products requiring durability | Four corner seals; stands upright; available in paper or plastic laminate materials; can hold 250–3000g |

| Flat Bottom Bags / Flat Bottom Pouches | Premium packaging for coffee, tea, snacks; offers stable shelf display | Flat base with gussets on all sides; combines features of stand-up pouch and box pouch; available with zipper or valve |

| Side Seal Bags | Common for coffee and tea packaging; can include a valve for freshness | Sealed along one side; available in paper or plastic laminate; holds 250–3000g |

| Window Bags | Allows visibility of product; used for snacks, dry goods | One transparent side (window) and one opaque side; often three-layer structure |

| Side Gusset Pouches / Fin/Lap Seal with Gusset | Used for coffee, tea, and similar products; offers more volume without increasing pouch width | Side gussets expand for extra capacity; flat bottom; sealed with fin or lap seal |

| Spouted Pouches | Used for liquid or semi-liquid products like juice, baby food, sauces | Stand-up pouch with spout for pouring; resealable cap; suitable for hot or cold fill |

| Pillow Pouches | Ideal for snacks, candies, coffee, seasonings, and other food items; offers a versatile and cost-effective packaging solution | Pillow-style three-side seal design; suitable for small to medium products; simple appearance; easy to stack |

| Packaging Film / Roll Stock | Used for automated packaging lines for food or other products; commonly used for snacks, instant noodles, candies, etc. | Roll-form film; customizable barrier properties such as oxygen, moisture, and light resistance; requires secondary processing into pouches; suitable for high-speed automation |

| Fin/Lap Seal Bags | Enhances sealing and protection performance; suitable for products requiring high sealing protection | Fold-over seam sealing; available in fin seal or lap seal; sealing style affects both appearance and sealing performance |

| Child Resistant Bags | Prevents accidental opening by children; commonly used for pharmaceuticals, chemicals, THC-containing products, etc. | Special safety design requiring specific operations to open; increases product safety |

Choose the Right Mylar Material Structure

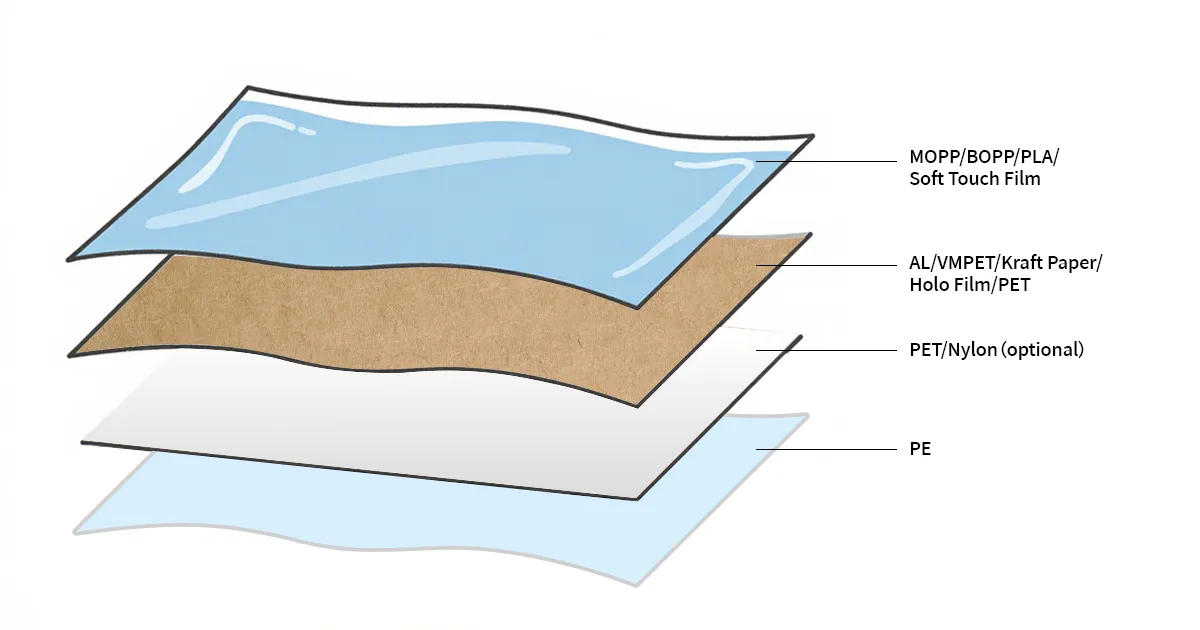

Mylar bags are usually made from multi-layer laminated films. The choice of material structure affects appearance, barrier properties, and cost. A typical laminated structure includes: Outer Layer + Middle Layer(s) + Inner Layer. The middle layer can be one or two layers.

| Layer | Material | Thickness | Key Features | Common Uses |

| Outer Layer | MOPP | 0.025(mm) | Good printability, premium matte look | Premium food packaging, coffee bags |

| BOPP | 0.025(mm) | High clarity, strong barrier properties | Snack packaging, retail display bags | |

| PLA | 0.02(mm) | Biodegradable, eco-friendly, compatible with kraft paper | Eco-conscious product packaging | |

| Soft Touch Film | 0.025(mm) | Premium tactile feel, scratch-resistant | Luxury food and cosmetic packaging | |

| Middle Layer | Metallic Barrier Film | 0.012(mm) | Excellent light/oxygen/moisture barrier, tear-resistant | Coffee, tea, perishable goods |

| White Kraft Paper / Brown Kraft Paper | 0.08(mm) | Biodegradable, premium look | Eco-friendly food packaging | |

| Holographic Barrier Film | 0.012(mm) | Excellent barrier properties, eye-catching design | Premium snacks, promotional packaging | |

| Clear Barrier Film / Nylon (NY) | 0.025(mm) | Strong, suitable for heavy products (>1.5 kg) | Bulk food packaging, heavy-duty products | |

| Inner Layer | PE | 0.08(mm) | Food-safe, flexible, heat-sealable | Inner seal layer for most Mylar bags (80% usage) |

Key Considerations:

Barrier performance — measured by OTR (Oxygen Transmission Rate) and MVTR (Moisture Vapor Transmission Rate)

Thickness — affects durability and flexibility

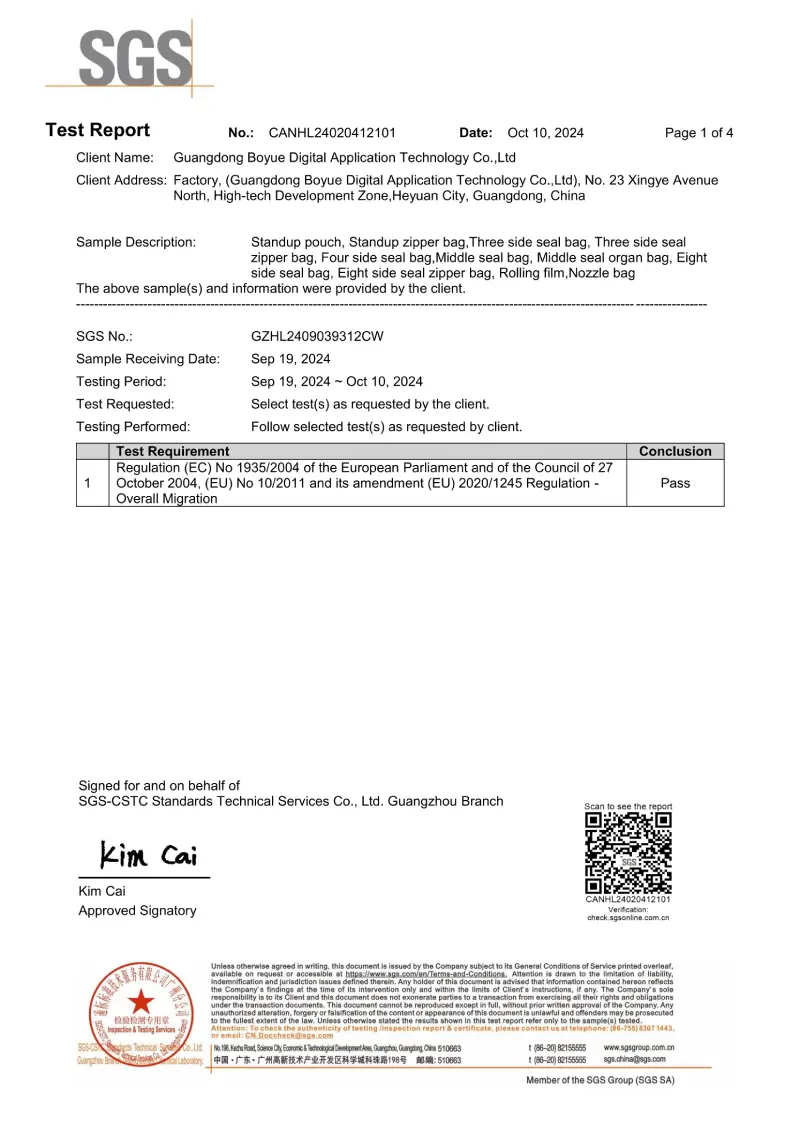

Food contact compliance — e.g., FDA (U.S.), EU 1935/2004 regulations

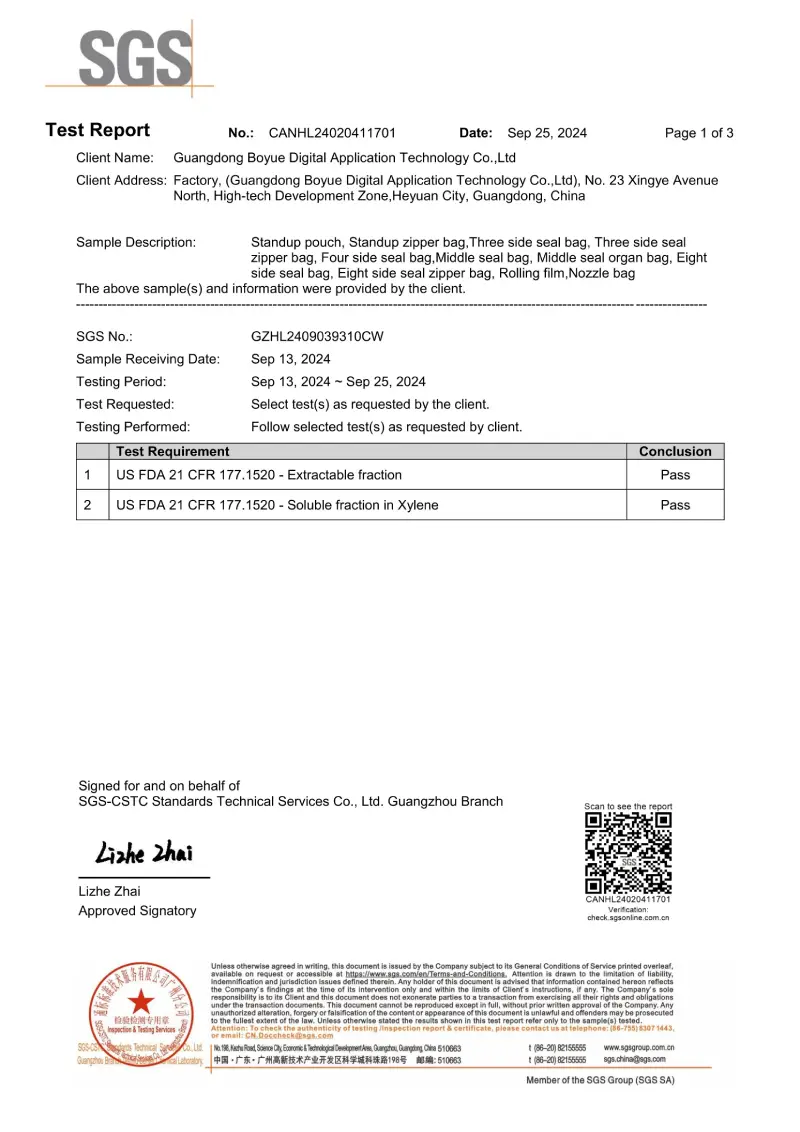

Boyue Printing's materials are all FDA and EU compliant and come with limited certification. We can collaborate with you for custom requirements.

Surface Finishes & Functional Add-Ons

Beyond selecting the bag type and material structure, surface finishes and functional add-ons play a critical role in both brand presentation and product performance.

| Feature | Type | Effect |

| UV Glossy Coating | / | Creates a high-gloss finish; makes colors more vivid and eye-catching. |

| Foil Stamping | gold, rose gold foil, holo foil, silver foil and more | Adds metallic shine with gold, silver, or custom foil colors. |

| Hang Hole | Round holes and Euro Slot | Punches a hole for hanging; improves display visibility. |

| Zipper | Zipper, Easy Tear -Off Zipper, and Child-resistant Zipper | Provides resealable closure; maintains freshness and prevents leakage. |

| Spouts | / | Allows easy pouring for liquids or semi-liquids. |

| Degassing Valve | One-way valve | Releases internal gas without letting air in; prevents oxidation. |

Design Your Custom Mylar Bag

A well-executed design not only protects your product but also strengthens your brand identity. Start by incorporating your core brand elements — logo, brand colors, typography, and distinctive patterns — to create a consistent visual presence across all packaging. Consider how your target audience will interact with the bag on the shelf or online, and ensure the design communicates your product’s value at a glance.

A well-executed design not only protects your product but also strengthens your brand identity. Start by incorporating your core brand elements — logo, brand colors, typography, and distinctive patterns — to create a consistent visual presence across all packaging. Consider how your target audience will interact with the bag on the shelf or online, and ensure the design communicates your product’s value at a glance.

For print preparation, provide high-resolution artwork (at least 300 DPI) in CMYK color mode to ensure accurate color reproduction. Avoid using low-resolution images or RGB files, as they can lead to dull or inaccurate prints.

Common file formats accepted by printers include AI (Adobe Illustrator) for vector-based graphics, PSD (Photoshop) for layered designs, and PDF for finalized print-ready files.

During layout, follow the printer’s specifications for safe zones, bleed lines, and dielines. The safe zone ensures that important text or graphics are not cut off, bleed lines allow for edge-to-edge printing without white gaps, and dielines define the exact cut shape of the bag. These technical details help avoid costly design revisions and ensure the final product matches your creative vision.

💡 Tip: Request your supplier’s artwork template to ensure proper alignment and avoid production errors.

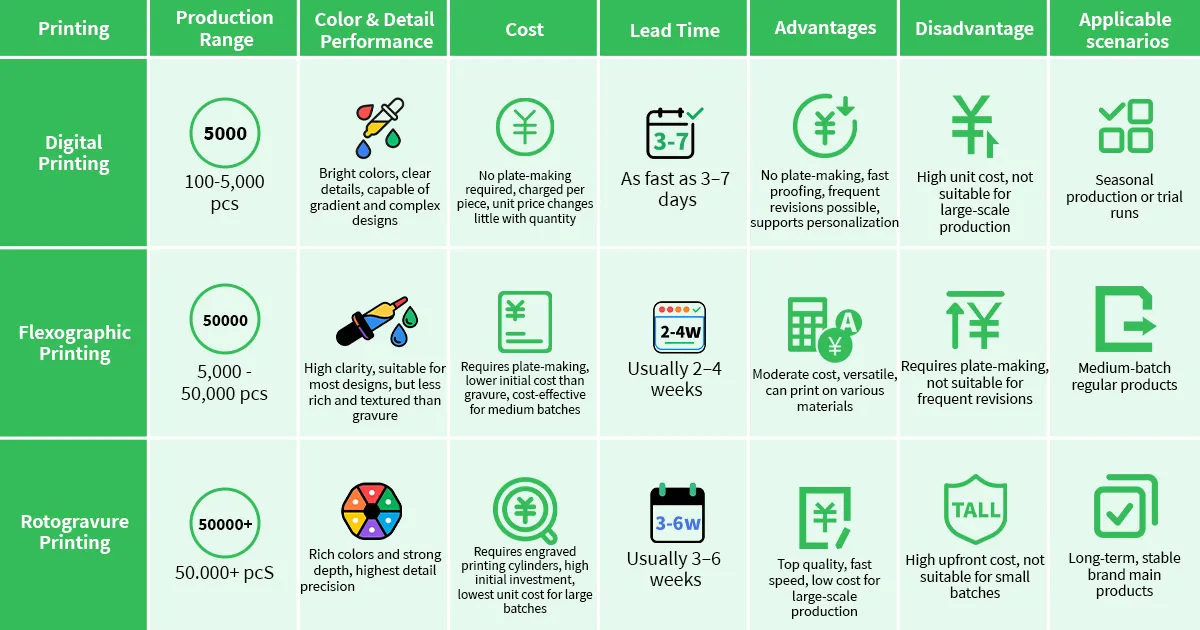

Select the Printing Method

Choosing the right printing method for your custom packaging is a balance between quantity, budget, and design complexity. Here’s a quick comparison to help you decide.

Digital Printing — Best for short runs, rapid prototyping, and designs that require frequent updates. It delivers vibrant, detailed colors without the need for printing plates, making it ideal for seasonal products or small-batch launches.

Flexographic Printing — A great choice for medium-volume production. It offers high clarity, consistent results, and works well across different substrates. Although it requires plate-making, the per-unit cost becomes competitive once you scale up.

Rotogravure Printing — Suited for large-scale production, delivering deep, saturated colors and precise detail. While cylinder engraving has a higher upfront cost, it provides the lowest per-unit price for bulk orders.

Cost & Lead Time Overview:

Digital Printing: Fastest turnaround (approx. 7–10 days), but highest per-unit cost for large runs.

Flexographic Printing: Lead time around 2–3 weeks due to plate preparation, with balanced costs for mid-range orders.

Rotogravure Printing: Lead time of 3–4 weeks for cylinder engraving, but most cost-effective for tens of thousands of units or more.

By matching your order volume, budget, and brand timeline to the right printing process, you can achieve optimal results without overspending.

Approve the Proof & Make Adjustments

Before moving into full-scale production, it’s critical to review and approve a proof to ensure your Mylar bag design meets expectations. Proofs generally come in two forms:

Digital Proof (Soft Proof) — A high-resolution digital file showing how the design will appear when printed. It’s quick to produce and ideal for checking layout, colors (approximate), and text accuracy, but it may not fully represent the final material or print effects.

Physical Sample (Hard Proof) — An actual printed bag using your chosen materials and printing method. This allows you to verify colors, finishes, and functional features under real conditions, but requires more time and cost to produce.

Kindly note that Digital Proof does not require any money, but physical sample does require a fee.

When reviewing a proof, check carefully for:

Color accuracy — Ensure brand colors and gradients match your design standards.

Typography & text clarity — Confirm that all words are spelled correctly and readable at actual size.

Alignment & positioning — Verify that logos, patterns, and design elements are properly placed and not cut off.

Functional performance — Test resealable zippers, tear notches, or other features to confirm usability.

Thorough proofing helps prevent costly errors, ensuring your final production run aligns perfectly with your vision.

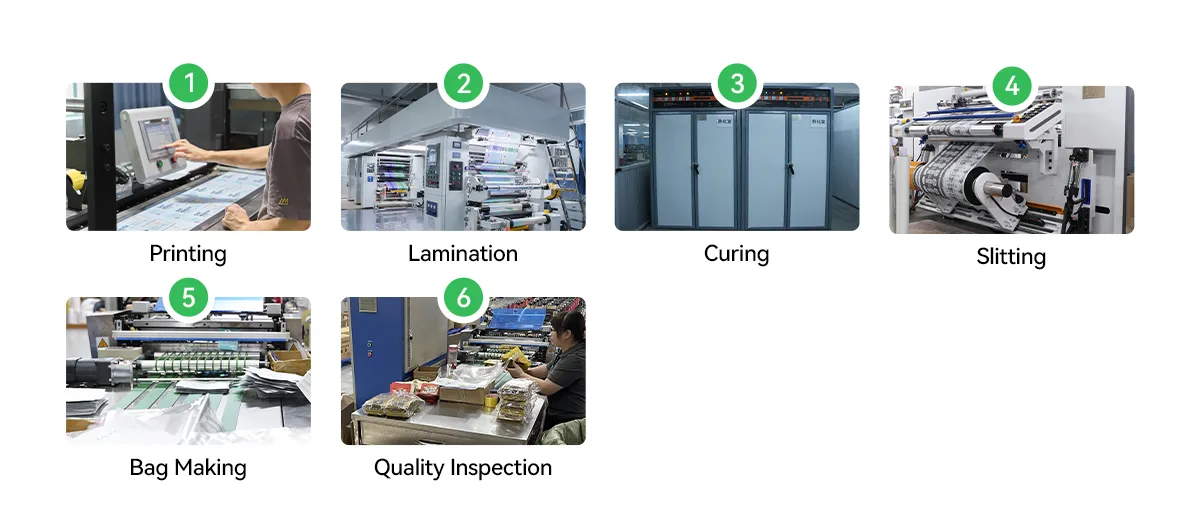

Customized Mylar Bag Production Process

After the above content is confirmed, production can be arranged. The manufacturing process of flexible packaging bags typically involves the following steps:

- Design & Plate Making – Based on customer requirements, the packaging bag’s style, dimensions, and printing content are designed, and the corresponding printing plates are produced.

- Printing – Using printing machines to transfer the designed patterns and text onto plastic films. Common printing methods include flexographic printing, rotogravure printing, letterpress printing, and digital printing.

- Lamination – Bonding the printed plastic film with other materials (such as aluminum foil or paper) to create a laminated film with moisture-proof, oxygen-resistant, and preservation properties.

- Bag Making – Cutting, heat-sealing, and shaping the laminated film into bags according to the pre-designed style and size.

- Inspection & Packaging – Conducting quality inspections on the finished bags, followed by packaging and processing for storage and transportation.

Note: The manufacturing process may vary depending on the type of flexible packaging bag. For example, liquid packaging bags also require additional processes such as filling and sealing.

Quality Control & Compliance

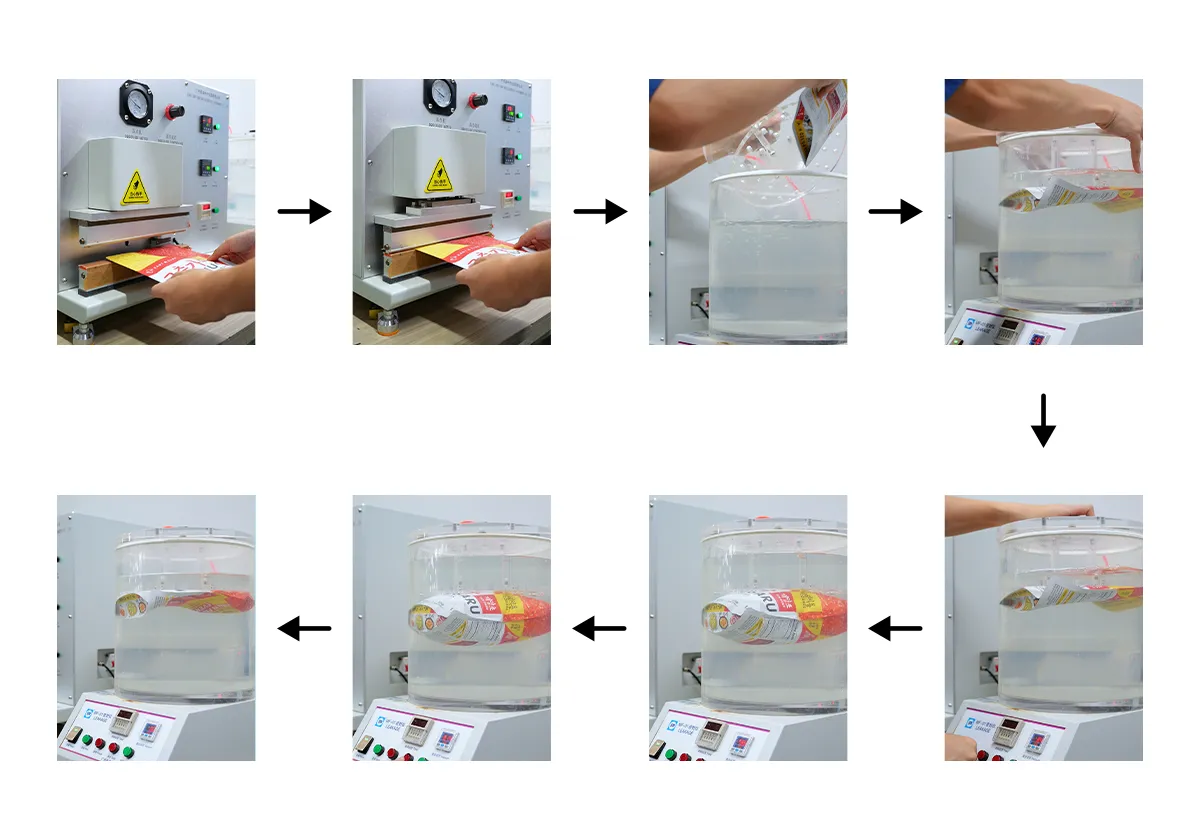

Before custom Mylar bags are approved for shipment, they must undergo rigorous quality control and compliance checks to ensure they meet both performance requirements and regulatory standards.

Physical Testing — This includes measuring film thickness to ensure consistency, evaluating heat seal strength to confirm leak-proof performance, and testing tensile properties to verify durability during handling and transport.

Barrier Property Testing — Oxygen Transmission Rate (OTR) and Water Vapor Transmission Rate (WVTR) tests are conducted to measure the bag’s ability to protect contents from oxidation and moisture, which is critical for products such as coffee, snacks, and pharmaceuticals.

Food Safety & Regulatory Compliance — For food-contact packaging, materials must comply with FDA (U.S. Food and Drug Administration) and EU food safety regulations to ensure they are non-toxic, free from harmful contaminants, and safe for direct contact with consumables. Packaging for regulated industries, such as pharmaceuticals or cannabis products, must also meet specific labeling, child-resistance, and tamper-evidence requirements.

By implementing thorough quality control procedures and adhering to international compliance standards, businesses can ensure product safety, maintain brand credibility, and meet the expectations of both retailers and end consumers.

Packaging & Delivery

Once the custom Mylar bags pass all quality checks, they move to the final stage — packaging and delivery.

Bulk Packaging Options — Depending on the bag type and customer requirements, Mylar bags can be packaged flat-packed (stacked in bundles) for easy handling and storage, or roll-packed for continuous-form bags used in automated filling machines. Flat packing is ideal for ready-to-use retail pouches, while roll packing offers efficiency for large-scale production lines.

Export Shipping Precautions — To ensure product integrity during transit, packaging should include moisture-proof protection (such as shrink wrapping or desiccant packs), compression resistance to prevent deformation, and UV shielding if prolonged exposure to sunlight is possible during shipping or warehousing. For international shipments, compliance with destination-country import regulations and labeling requirements is essential.

Lead Time Estimates — Typical lead times for production and delivery vary based on order size, customization complexity, and shipping method. For example, small digital-print runs may be ready in 1–2 weeks, while large rotogravure orders requiring overseas shipment can take 4–6 weeks from approval to delivery.

Carefully planned packaging and logistics ensure that the Mylar bags arrive in perfect condition, ready for filling, sealing, and distribution.

Tips for Businesses Ordering Custom Mylar Bags

When planning your custom Mylar bag order, a few strategic decisions can help you reduce costs, shorten lead times, and secure a reliable supply chain.

Lowering Unit Costs —

Order in Bulk: Larger quantities significantly reduce the per-unit price by spreading setup and printing costs across more units.

Optimize Materials: Select the most cost-effective material structure that still meets your product’s barrier requirements.

Shared Printing Runs: For smaller orders, consider combining production with other customers using the same printing method to share setup expenses.

Shortening Lead Times —

Finalize Designs Early: Confirm artwork, dielines, and material specifications before placing an order to avoid delays during pre-production.

Choose Local or Nearshore Suppliers: Working with suppliers closer to your market reduces shipping time and mitigates potential customs delays.

Supplier Selection Checklist —

Production Capacity: Can they handle your required volume within the desired timeframe?

Quality Systems: Do they have ISO certifications or documented quality control processes?

Proven Track Record: Review previous projects, especially in your industry.

After-Sales Support: Ensure they offer responsive customer service and solutions for defects or urgent reorders.

By following these tips, businesses can ensure a smoother production experience, avoid costly missteps, and secure packaging that delivers both functional performance and brand impact.

Conclusion

Custom Mylar bags give businesses control over brand image, product protection, and compliance with regulations. By understanding the step-by-step manufacturing process, you can better communicate with suppliers, avoid costly mistakes, and ensure your products stand out on the shelf.

Ready to start your custom Mylar bag project?

Share:

Recommended article

Categories

Not sure what to choose?

Skip the calculator. Our packaging team is here to guide you.

Talk to an Expert

Not sure what to choose?

Skip the calculator. Our packaging team is here to guide you.

Talk to an Expert

Not sure what to choose?

Skip the calculator. Our packaging team is here to guide you.

Talk to an Expert

Not sure what to choose?

Skip the calculator. Our packaging team is here to guide you.

Talk to an Expert

Not sure what to choose?

Skip the calculator. Our packaging team is here to guide you.

Talk to an Expert

Not sure what to choose?

Skip the calculator. Our packaging team is here to guide you.

Talk to an Expert

Ready to upgrade your packaging?